The Bite Test

In the early 1930s Lady Esther became the top-selling, loose face powder in the United States, a position it maintained for the rest of the decade. Commentators of the time attributed Lady Esther’s success largely to its advertising which monopolised the only practical field-test for measuring the fineness of face powders – the ‘bite test’.

Take a pinch of your powder and place it between your front teeth. Bring your teeth down on it and grind firmly. If there is any trace of grit in the powder it will be as instantly detectable as sand in spinach.

(Lady Esther advertisement, 1935)

See also: Lady Esther

The Lady Esther bite test advertising campaign began in 1933 and was so successful that it generated something close to panic in other American cosmetic companies.

A casual letter concerning the possibilities inherent in a new synthetic face powder base brought replies within forty-eight hours from thirteen of the fourteen executives to whom it was addressed and the last one followed during the course of the week. Probably no such response ever was received by a new cosmetic material. Such unanimity of interest is ample testimony of the general desire to get hold of something really new in face powder.

The “bite test” has bitten large chunks out of the sales of a good many face powder manufacturers. Now all are planning to bite back. Coty is experimenting with a new process to produce an improved powder; other prominent manufacturers are searching the earth for new materials and new processes—for anything that will give them good “copy hooks.”(Chilson, 1935)

Once the bite test was bought to everyone’s attention, cosmetic chemists worked to quantify it, to determine how small the particles of face powder would need to be to pass the test. The question was answered in 1937 when M. L. Smith published the results of his experiments on volunteers. As reported by deNavarre, Smith determined that the particles would need to be 12 microns (0.012 mm) or less to pass the test (deNavarre, 1942, p. 354). This was much smaller than the particles produced by the mixing and sifting methods then used by most powder manufacturers.

Mixing and sifting

Traditional methods of making face powder relied on sifting – either at the beginning of the powder making process, when the raw materials were added, or at the end, after the ingredients were combined – to remove large particles, extraneous matter, and other accumulations that might make face powder feel gritty; and mixing, to blend all the elements of the powder into an homogeneous mixture.

Most of the sieves used ito make face powders were in the 120 to 160-mesh range. Sieves in this mesh range allowed particles of over 100 microns to pass through them – well above the 12 micron limit established by Smith. Using a finer sieve would not help, as the practical limit of sieves was 400-mesh and even these would allow particles to pass through that were larger than 12 microns. This meant that no powder that relied on sifting to remove ‘grit’ would pass the bite test.

U.S. Standard Sieve No. Size of Particles in Microns 50 297 100 149 200 74 325 44 625 20 (deNavarre, 1942, p. 354)

Micro-sized powders

Clearly, Lady Esther had managed to make its face powder with particles that were under 12 microns. Some of the materials used in face powders in the 1920s were already smaller than this – e.g., rice starch granules were generally in the range of 3-8 microns – but for the other ingredients manufacturers had two choices; substituting coarser substances with other materials such as those produced by electrostatic precipitation; or grinding the powders finer with newer machines such as pulverisers.

Electrostatic precipitation: Earlier in the century it had been discovered that some materials could be produced in an extremely fine, pure form if an electric current was used to deposit them onto an electrode. Electrostatic precipitation separated out coarser particles and impurities and produced a more homogeneous product in which particles were very, very small. Using this process manufacturers could substitute coarse forms of powders, like kaolin and chalk (calcium carbonate), for forms that were less than 12 microns in size.

Pulverisation: Material used in face powders could also be made finer than 12 microns by putting them through one of the improved grinding machines that came onto the market in the 1930s. These ‘pulverisers’ reduced materials to a very fine powder through grinding and, although more expensive, they could operate without sifters.

The Pulverizer Method

This is the fastest method, but is applicable only to fairly large production. It is at once the fastest and most economical method of making face powder. When properly handled, face powder made this way requires no sifting. The batch is given a preliminary fifteen minute mix in a mixer together with color and perfume. It is then fed to the pulverizer which will handle it at a rate from 500 to 1,000 pounds per hour. Pulverizers are variously called disintegrators, hammer mills, attrition mills, disc mills, cage mills depending upon the nature of their milling mechanism. All are similar in principle and all operate at speeds ranging from 5 to 10 thousand revolutions per minute.(Chilson, 1934, p. 68)

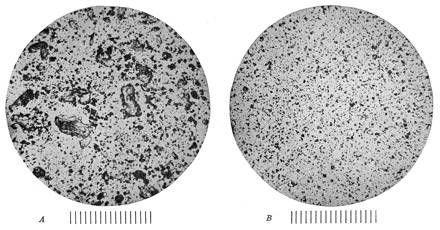

Above: (A) Regular face powder colour particles. (B) Micronised colour particles. Each division under the images is 10 microns (Modified from deNavarre, 1941).

See also: Loose Face Powders

Other manufacturers could also use these technical advances and have their powders pass the bite test. The main issue for smaller companies was the increase in costs. Larger firms could absorb the extra costs but they still needed a marketing edge to go with their adoption of finer powders, as any mention of the bite test would automatically make customers think of Lady Esther.

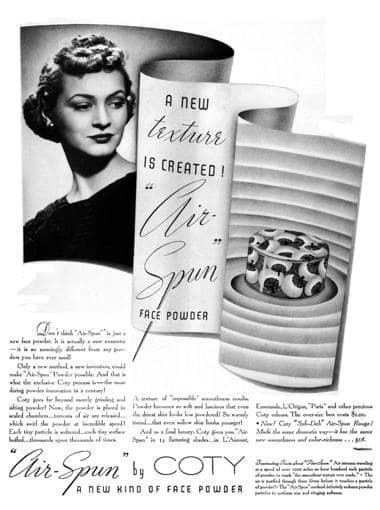

Some larger companies found a way out of this dilemma. For example, in 1935, Coty secured the exclusive rights to make their powders using air-powered micronisers and began marketing them as ‘Air Spun’. Bourjois’s response was to advertise that their face powders had ‘Skin Affinity’, that each “particle of powder is from two to three times smaller than those in many other popular powders; also much more uniform in size and shape” (Bourjois advertisement, 1938), and included some photomicrographs of powder particles to make sure the reader got the message.

See also: Coty ‘Air Spun’

Powder fineness

By the 1940s, technical advances enabled cosmetic companies to produce powders of a fineness that could have only been imagined in previous decades.

It must be remembered that a “fine powder” is, of course, a relative term. A generation of so ago “200 mesh” was considered very fine. Nowadays a 50-75 micron particle seems rather coarse, and a material needs to be below 10 microns in size to be thought of as an “impalpable” powder. Perhaps in another twenty years even particles of 10 microns might be thought of to be boulder-like, and the public demand may be for something finer still.

(Hibbott, 1947, p. 271)

Hibbott’s comments are prescient. In these days of mineral make-up, 10 micron particles are considered ‘coarse’ and 2-3 micron particles are seen as ‘fine’. Things have come a long way since the 1930s when there were warnings about particles being too large. Now, with the introduction of nanoparticles and microplastics, there are serious questions about cosmetic powder particles being too small.

First Posted: 1st July 2013

Last Update: 14th January 2024

Sources

Chilson, F. (1934). Modern cosmetics. New York: Drug & Cosmetic Industry.

Chilson, F. (1935). The trends in face powder. The Drug and Cosmetic Industry. 36(6), 685-686.

Collingridge, G. S. (1937). Modern face powders. Manufacturing Perfumer. October, 209-212.

deNavarre, M. G., & Maicki, R. J. (1938). The new face powders. The American Perfumer & Essential Oil Review. February, 33-34.

deNavarre, M. G. (1941). The chemistry and manufacture of cosmetics. Boston: D. Van Nostrand Company.

Hibbott, H. W. (1947). Particle size relationships in face powders. The American Perfumer & Essential Oil Review. August, 269-271.

Poucher, W. A. (1932). Perfumes, cosmetics and soaps (4th ed., Vol. 2). London: Chapman & Hall Ltd.

1934 Lady Esther “Bite-Test”.

1935 Lady Esther face powders.

1935 Tokalon Ltd. (London) copy of the bite test.

1937 Coty Air Spun face powders.

1938 Bourjois Face Powder with Skin Affinity.