Nail Polishes/Enamels

Until the 1920s, most people used a polishing powder to shine the nail plate. They came in many forms – sticks, blocks, pastes, loose powder and even liquids – but all contained fine abrasives that were combined with buffing to make the nail plate shine.

See also: Nail Powder Polishes

Powder polishes are still around today but they have been largely superseded by liquids painted on the nails to produce a more or less instant shine. Early forms were colourless or a pale pink and were made with a variety of materials – waxes, shellac, and gum benzoin – with later forms mostly made with nitrocellulose.

Wax polishes

Many paste polishing powders used waxes to help suspend the powder, thicken the paste and add shine. If the abrasive was left out then any shine produced would be due solely to the wax. This polished the nail plate in the same way that a polishing wax makes wood furniture shine. Like them, a shine was produced by gently buffing the nail plate with a chamois or something similar after the wax was applied.

Wax nail polishes without abrasives were made as pastes or liquids and what they lacked in effectiveness they made up for in simplicity of manufacture. Paste wax polishes were simple mixtures of substances like beeswax, ceresine, spermaceti, and soft paraffin, which were melted together and poured into small pots.

100 White beeswax. 100 Ceresine—white—high M. P. 800 Soft paraffin—white. 1000 (Poucher, 1932, p. 480)

Liquid wax polishes were made by dissolving the wax in a suitable solvent, either cold or gently warmed in a steam-heated mixing bowl. When applied to the nail plate the solvent evapourated leaving a thin layer of wax behind. As the solvent used was highly volatile, these liquid polishes had to be sold in sealed, stoppered bottles to stop them drying out.

Chloroform 150 grams Paraffin wax 15 grams Perfume with a little essence of rose or geranium.

(Durvelle, 1923, p. 264)

25 White wax. 50 Hard paraffin. 1000 Chloroform. 1075 (Poucher, 1932, p. 481)

Wax polishes were also made in stick form. Looking a little like a lipstick they were easy to carry and apply but, like other wax polishes, they also required buffing after the stick was rubbed across the nail plate.

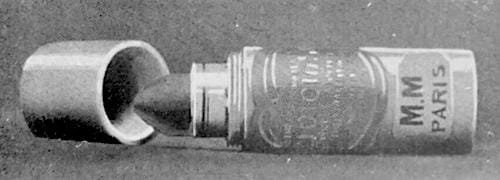

Above: 1916 A Baton de Cosmetique produced by Maison Marcelin Maire, 227 Rue Saint-Denis, Paris.

Solvents and films

Liquid wax polishes were the first nail polishes that used a solvent to deposit a film on the nail plate. The film helped protect the nail and maintain the shine for a longer period of time, thereby reducing the need to rebuff the nail. They were often applied on a nail that had first been buffed with a polishing powder – so they simply helped to preserve the polished surface – but they could also be subjected to further buffing after the wax polish had dried.

When nitrocellulose polishes appeared, the need for buffing was reduced and eventually disappeared. However, it did not disappear altogether and references to buffing – either before or after applying a nitrocellulose polish – were still occurring up until the outbreak of the Second World War. Some of this was habit but early formulations sometimes required buffing after they were applied to bring out their best shine.

Before applying varnish, if it is to be used, the nails must be well polished with the buffer and one of the various preparations now in favour, which are generally made in stone, powder, or cream form. … Never apply varnish to a nail that has not been burnished in this way; otherwise the natural gloss of the nail will eventually disappear. … Care must be taken in its application to obtain an even surface. Work is always from the lunule down towards the finger-tips.

Many French women to-day varnish from the entire base right over the nail. This is not really very becoming. The half moon showing is always rather intriguing. Dip the brush in the varnish and then press against the bottle so that only a portion remains on it; this guards against and excess of varnish, which usually results in a blob on the nail. Make an even sweep with the brush from the half-moon down to within ½ in. from the edge, or where it can bee seen that the nail ceases to adhere to the flesh. The amount on the brush is usually sufficient for two lengths of the nail. Be careful not to allow the varnish to contact with the edges of the cuticle, as this spoils the effect. Allow to dry and apply a second coat, and once again when the enamel has completely dried use the buffer.(Hanckel, 1937, pp. 137-138)

Varnishes and lacquers

Once the idea of applying a film of polish to the nail with a suitable solvent was developed, cosmetic chemists experimented with other varnishes and lacquers – such as shellac, gum benzoin and cellulose nitrate (nitrocellulose) – many of which had been developed in the nineteenth century. Liquid nail polishes using these vanishes and lacquers began to appear early in the twentieth century but it took a while for serviceable polishes to be developed and for the idea to spread.

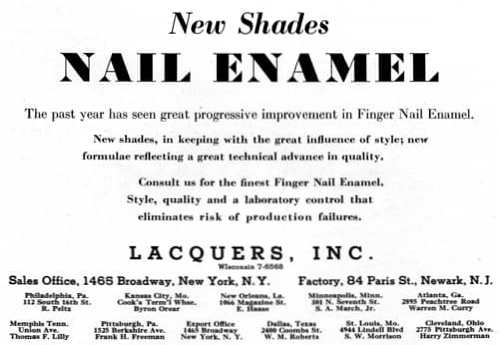

Nail polishes made with industrial lacquers and varnishes were usually sourced from lacquer firms that had the technical knowledge to deal with these dangerous materials and the capacity to produce polish in bulk. This left nail polish companies with the relatively simple task of bottling and packaging the polish which made it easier for them to start a new business. A number of nail polish companies began this way including Revlon.

The wise manufacturer selects one of the private label houses to make his enamel. Elaborations and special effects can be worked out.

The danger from fire—perhaps even explosions—is so great that the risk isn’t worth the result. Private label houses in many cases have spent years in perfecting their clear lacquer. They have studied every conceivable coloring material and know its behavior in nail lacquer. Most of all they know the dangers of the business and are adequately protected.

Many successful businesses have been built in this field by delegating the manufacture of nail lacquer to the private label house.(deNavarre, 1941, p. 577)

Above: 1938 Lacquers, Inc., an American private label company, advertising new shades of nail enamel.

See also: Revlon

Given the relationship between nail polishes and the varnish and lacquer industry, it is understandable that many early liquid nail polishes were known as varnishes or lacquers. However, they were also referred to as polishes or enamels by cosmetic companies and beauty writers of the time. Unfortunately, the story of nail polish in the early twentieth century is muddied by the fact that the terms polish, lacquer, varnish, and enamel were used haphazardly and covered a wide range of nail product types not all of which were nail polishes as we understand them today.

Benzoin polishes

Benzoin-based nail polishes provided a reasonably good shine to the nail but were slow to dry, required buffing to bring out the gloss, and had a tendency to become brownish in colour. This meant they could not compete with cellulose nitrate polishes in the long run.

Poucher (1932) includes a formulation for a gum benzoin polish, tinted pink with a small amount of eosin – perhaps to hide the brown – but a similar product could be made that was clear.

Benzoin Nail Enamel is conveniently prepared from the resinodor as follows:—

200 Benzoin R. 400 Alcohol. 400 Ether meth. .753. 1 Methyl acetophenone. 0.2 5 per cent solution of eosin. 1001 Mix the liquids and apply to the nail with a camel’s-hair brush. Allow the first coating to dry three minutes, then apply a second one. Dry for 10 minutes, and then polish with a silk handkerchief.

A perfect result is obtained and the nails will remain brilliant for several days.(Poucher, 1932, p. 481)

Nitrocellulose polishes

Nitrocellulose – also known as cellulose nitrate – is produced by immersing cellulose in nitric acid, or a mixture of nitric and sulphuric acids, for a short time. A common source for the cellulose in the United States was cotton and when this was nitrated it was known there by such names as pyroxylin, nitrocellulose, nitrocotton, soluble cotton, or guncotton, in part depending on the composition of the cellulose nitrate which varied according to how much the cotton had been acted on by the nitric acid.

A number of uses were found for cellulose nitrate in the nineteenth century including the manufacture of explosives, celluloid (an early plastic), nitrate film stock, varnishes, and artificial silk. Some of these technologies relied on the fact that partially nitrated cellulose could be dissolved in organic solvents – like alcohol, ether and acetone – and when these evaporated a clear film was left behind.

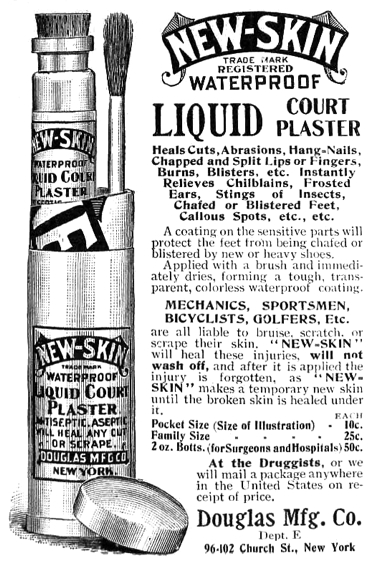

Understandably, it was not long before nitrocellulose was being used in nail polishes. Historically, these appear to have come from developments in a medical dressing called a Liquid Court Paster made from Collodoin, also derived from cotton.

Collodion and liquid court plasters

Collodion was first produced in 1846 when Louis-Nicolas Ménard [1822-1901] and Florès Domonte produced a clear gelatinous liquid by dissolving pyroxylin (a partially nitrated cotton) in a mixture of ethyl alcohol and ether. The following year, its discovery was put to good use when John Parker Maynard [1817-1898], a Boston physician, discovered that dried collodion formed a clear, waterproof, protective film over a wound. Maynard’s discovery gained wide medical acceptance and led to a number of commercial forms of this liquid medical dressing being put on the market, generally badged as liquid court plasters.

Early liquid court plasters tended to contract and crack on drying but a flexible form was later developed – an important advance. It used plasticisers like Canada balsam and castor oil to produce a film that could bend and flex with the skin.

In 1882, John H. Stevens [1853-1932] patented the use of amyl acetate as a solvent for pyroxylin. It produced a more durable, transparent film than one generated from using ethyl alcohol and ether and it found a number of industrial uses including the development of nitrocellulose-based wood and metal lacquers.

Liquid court plasters were also formulated using amyl acetate rather than ethyl alcohol and ether.

Liquid Court Plaster …

The following formula is also used to a considerable extent:

Pyroxylin 1 ounce. Amyl acetate 6 fluidounces. Acetone 5 fluidounces. Camphor 2 drachms. Fir balsam 2 fluidrachms. Castor oil 8 fluidrachms. Oil of cloves 15 minims. Dissolve the pyroxylin in the amyl acetate and the acetone, and add the other ingredients. Keep the mixture away from fire. It is essential that a good grade of pyroxylin be used.

(Bulletin of Pharmacy, 1916, p. 214)

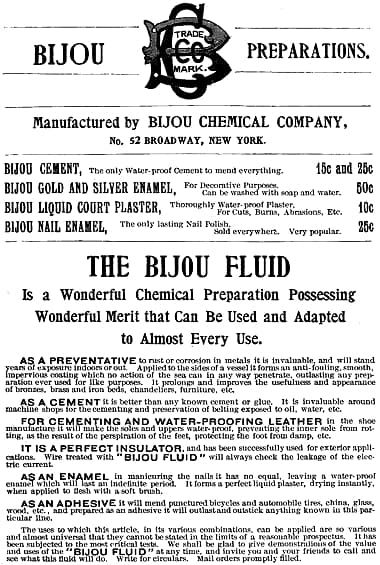

Exactly when these nitrocellulose-based medical dressings began to be formulated as nail polishes is an open question, with most cosmetic chemists placing this landmark event in the history of nail polish in the late 1910s or early 1920s. However, evidence suggests that it took place a good deal earlier than this. For example, the Bijou Chemical Company of New York was putting their Bijou Fluid into a nail polish/enamel at least as early as 1902. Given that this preparation also formed the basis for their liquid court plaster, a metal lacquer, an adhesive, and a leather waterproofer, there seems little doubt that Bijou Fluid was a flexible collodion containing nitrocellulose, and that their nail polish was nitrocellulose-based.

THE BIJOU FLUID …

As an enamel in manicuring the nails, it has no equal, leaving a waterproof enamel that will last.(Bijuo Chemical Company advertisement, 1902)

Unfortunately, as I have already noted, the situation regarding liquid nail polishes produced before 1920 is far from clear. There were numerous liquid nail polishes on the market before 1919, but, without access to their original formulation, it is difficult to know whether they were made as liquid abrasive powders, liquid waxes, liquid benzoin polishes, or liquid nitrocellulose polishes.

Nail polish and automobile paint

One reason why some have suggested that nitrocellulose nail polishes were developed in the 1920s is the belief that they were inspired by developments in glossy car paint, specifically the Duco Paint that E. I. du Pont de Nemours developed for General Motors in 1923. This seems unlikely. Duco Paint was based on nitrocellulose, came in a wide range of colours, and was advertised as having a fast-drying, tough, durable, waterproof finish but it was designed to be sprayed not painted on, required at least twelve hours, not minutes, to dry, and only had a satin sheen so required further polishing to develop a high gloss (E. I. du Pont de Nemours, 1925). This, and the 1923 date, suggests that the development of Duco Paint coincided with a greater use of nitrocellulose in nail polish but was not directly responsible for it. Both products evolved from developments in the varnish and lacquer industries.

Celluloid film stock and nail polish

Nitrate (celluloid) film was patented by Hannibal Williston Goodwin [1822-1900] in 1898. The idea was later reinvented by the Eastman Kodak Company which triggered a legal dispute that was not settled until 1914. Eastman Kodak reportedly made their celluloid film stock by dissolving pyroxylin in a mixture of methyl alcohol, amyl alcohol, and amyl acetate (Sabin, 1904, p. 113). Camphor was added as a plasticiser and the resulting film was then coated with a photosensitive gelatine emulsion.

Given that nitrate film was liable to catch fire, it was dangerous to store and was often sold as scrap after a movie had played out in the theatres. A nail polish could be made from this film scrap by stripping off the gelatine and then dissolving the remaining film in amyl acetate and acetone or with other solvents.

The preparation used by photographers which consists of celluloid obtained from scrap sources and dissolved in amyl acetate is widely employed.

The work consists of cutting up the scrap and charging into a comparatively large mixing pan, because of the space occupied. Amyl acetate and acetone are poured into the pan, and heat gently applied.

The consistency of the product can be varied by the amount of scrap added, and should be reduced to a syrupy condition. some selected perfume is then added in the usual manner, and the charge emptied.(Arend, 1935, p. 123)

Scrap celluloid was widely used to make nail polish early on but the practice began to disappear in the 1930s. Using scrap celluloid film was cheaper but any presence of synthetic camphor adversely affected the brightness of the finished nail polish so its use had declined by the time the Second World War broke out. When nitrocellulose supplies were diverted for the war effort there was a renewed interest in using celluloid film stock but this faded when normal supplies resumed after 1945.

A British wartime recipe:

The following formula has been devised with the idea of getting a reasonable result when using scrap film, and it is left to individual initiative to replace any items in it with anything similar which may be more readily available.

Parts by weight Industrial methylated spirits 70 Butyl acetate 70 Castor oil 1 Scrap (nitro) film 14 Water white rosin 7 162 (Holmes, 1942, p. 118)

Colour

The first nitrocellulose nail polishes were generally made in a clear ‘Colourless’ or pink ‘Natural’ shades with the pink colour produced with dyes like carmoisine, safranine, erythrosine, or phloxine. By the end of the 1920s, nail colour had become more obvious, with many companies making enough shades to enable nail polish to match the colour of the clothing or jewellery a woman was wearing. Mother of pearl polishes, made by adding in fish-scale essence, had also made an appearance by then.

Many nail polish companies made polishes in a wide range of colours, but manicurists could also mix up shades to meet the needs of individual clients. Unfortunately, it is not clear how they did this for their society clients. Some materials such as gold, silver or pearl powder could be mixed directly into a clear polish as could some colours. It is also possible that manicurists first applied colour to the nail and then covered this with a clear nail polish. Clients could return the following day to have it replaced with something more suitable or use a remover.

Very pink finger nails and sometimes blood red nails have been popular for some time with women in London. The latest idea, however, is to have finger-nails to match dresses. At a recent function a lady was observed in a Parma violet chiffon frock, and Parma violet finger-nails to tone exactly. The idea is an off-shoot of the matching craze which is sweeping over London and Paris just now.

A well-known London beauty specialist is pushing the craze, and her clients arrive with samples of the frocks they will wear in the evening to have their nails “done!”. Mauve, violet, blues, greens, orange, yellows and reds are used. One girl wearing a pearl-colored satin frock had her fingertips enameled a loverly pearly tint, which looked really pretty. The enamel comes off quite easily with a special preparation used for the purpose, so that there is no fear of one’s blue or green fingers clashing next morning with one’s favourite orange jumper suit.(AP&EOR, 1929)

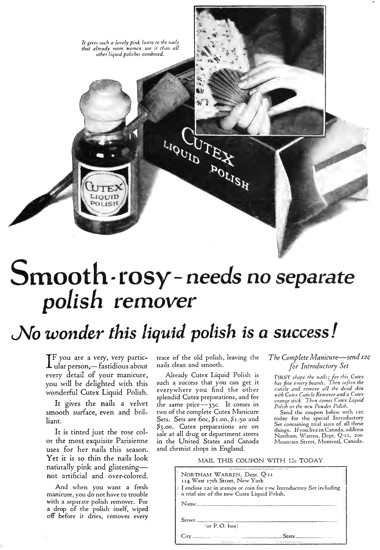

Some nail polish firms used this idea as well. Cutex, for example, sold a clear nail polish in the 1920s that came with a separate tint that could be used to produce a polish with varying degrees of colour.

In the more sombre depression years of the 1930s, bright colours went out of fashion and were replaced by subdued reds and smokey-reds.

Lately the cult of the coloured fingernail—gold, mother of pearl, blood red, or tinted to match the gown—marks us as too hand conscious. Pointed fingers with nails trained like pencil-tips, and coloured in unnatural tones, makes loverly hands look like the claws of some exotic bird and not the warm and human hands that have charmed lovers down the ages.

(Harper’s Bazaar, 1930)

Transparent polish

With the exception of pearl and metallic types, most nail polishes used in the 1920s were transparent, either clear or coloured with dissolved dyes. They were generally applied across the centre of the nail, leaving the lunula (half moon) and free edge visible as this was believed to make the fingers look long and elegant. The free edge was either kept clear of polish or coloured underneath with a nail white to make it stand out. The half moon was similarly treated and, if a woman did not have one, a skilled manicurist could paint one in.

[O]ne often finds clients with little or no half-moon showing, and it is not always possible to reveal the half-moon or lunular without a lengthy treatment. But in order to create the necessary effect, one can use a slightly deeper liquid polish, leaving a suitable unpolished curved base. This resembles the natural lunular so closely that the difference will hardly be noticed.

(Nail Culture, 1934, p. 12)

Above: Carol Lombard in the 1930s showing a set of polished nails with a distinctive half moon and free edge.

Opaque (cream) polish

By 1930, opaque (cream) nail polishes were becoming fashionable in Europe with some suggesting that the deeper colours produced by cream polishes went better with the darker skin tones produced by sun bathing, a vogue that became increasingly popular in the 1920s.

Initially, these cream polishes were made by European companies or smaller American firms that had a presence in Europe. They became more common in the United States after Revlon started up in 1932 and Cutex began selling them in 1934.

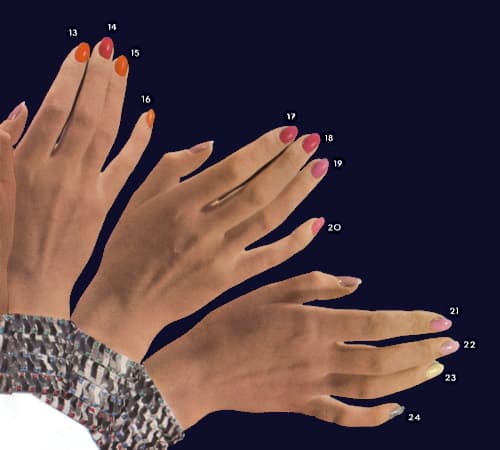

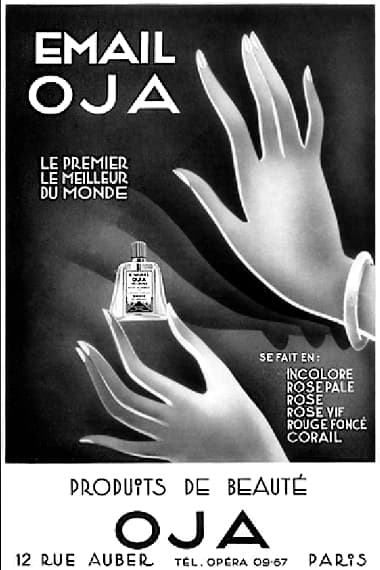

Above: 1935 Some nail polish shades from Votre Beauté, a French beauty magazine. The shades could be obtained from a variety of companies. For example, No. 17 was available as the Laque Rose shade from Elizabeth Arden, Rose Foncé from Eclador, Rosée from Klytia, Naturelle from Molyneux, Rose Vif from Oja, Blush Rose from Peggy Sage, Rose Foncé from Robel, and Marbré Vif from Lam-Lak.

Cream polishes were made by adding titanium dioxide and coloured pigments like iron oxides into the polish mix. As well as being opaque, cream nail polishes came to redefined the way the polish was applied to the nail. Revlon recommended applying them over the entire nail plate from the base of the nail to the free edge. This required less skill, covered nail defects and made the polish more striking. One disadvantage of covering the polish across the free edge was that the nails were more likely to show chips and some nail polish companies stayed with keeping the free edge and half moon free of polish. White could also be used to colour the free edge to create what became known as a french manicure.

Revlon also pushed the idea that nail polish colours were a fashion item and, like clothing, needed changing each spring and autumn. This meant that nail polish companies began to launch new colours on a seasonal basis, requiring fashion conscious women to purchase new shades before older ones were used up.

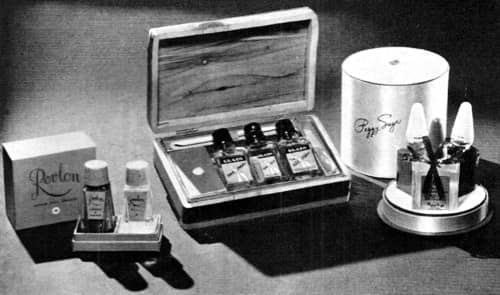

Above: 1939 Nail polishes, enamels and varnishes from Revlon, Amani, Manex, Keenes and Cutex.

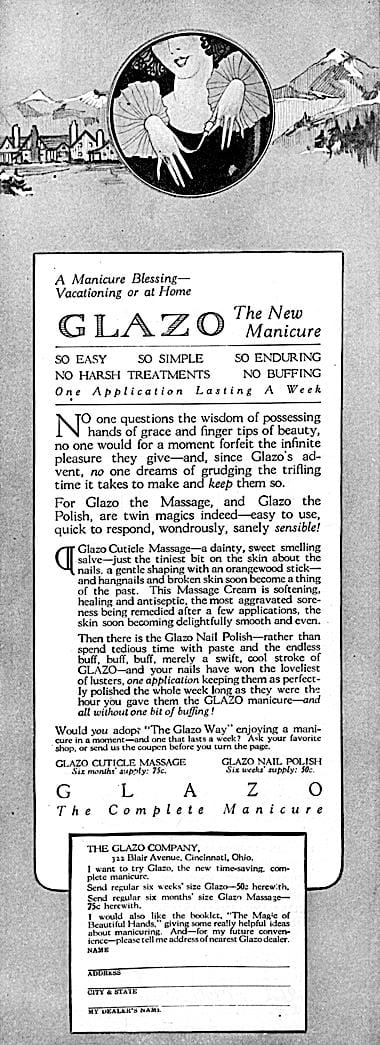

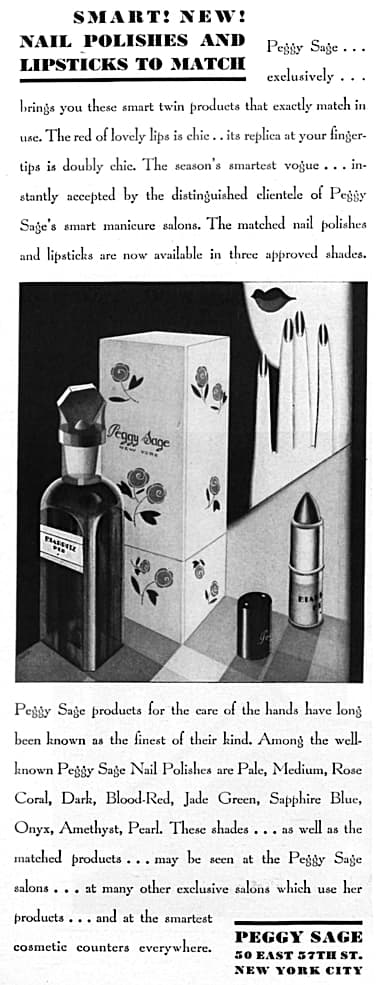

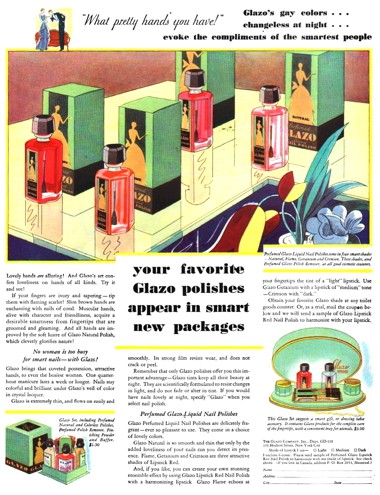

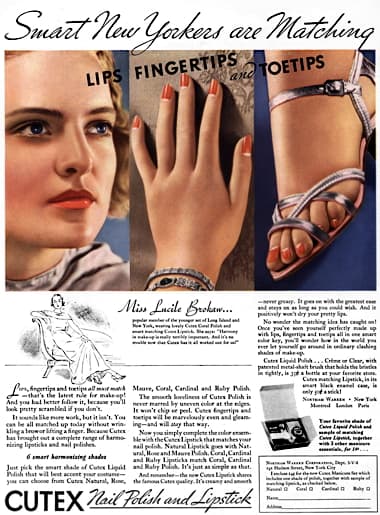

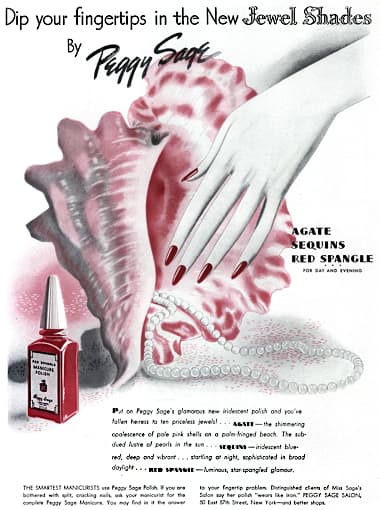

When Revlon began to make lipsticks in 1939, they heavily promoted the notion that nail polish and lipstick should match, a fashionable French trend that had first appeared in the 1920s. Other American companies, such as Peggy Sage and Glazo, were producing nail polish shades to match lipsticks no later than 1930. Peggy Sage nail polishes were also matched with lipsticks from companies such as Schiaparelli, Lelong, Lentheric, Charles of the Ritz, Du Barry, Dorothy Gray, and Coty, when Revlon became a much bigger threat in the late 1930s.

See also: Peggy Sage (post 1940)

Other cosmetic companies had also adopted this idea earlier in the decade. For example, in 1931, Helen Rubinstein sold lipsticks, rouge and Nail Groom (her nail polish) in matching Red Geranium, Red Raspberry, and Coral shades.

See also: Helena Rubinstein (1930-1950)

‘Modern’ nail polish

By 1930, there was a general agreement about the characteristics of an ideal liquid nail polish. It should be harmless, easy to apply, dry quickly and evenly, harden well, resist chipping and abrasion, be waterproof, have an even colour that did not stain the nail, be stable in the bottle, and have a pleasant smell. Unfortunately, early nitrocellulose nail polish formulations did not have all of these qualities. Their adhesion was poor, if coloured they often stained the nail, and they took a relatively long time to dry. Many early nail polishes did not even have a dedicated nail polish remover, and were taken off by applying another layer of polish or by using neat acetone.

The use of nail enamel is now almost universal. It is a rapid means of acquiring a brilliant lustrous finish and may, if desired, be applied without previously burnishing the nails. The only disadvantage it possesses is that of coming off in streaks after a few days. This is not very noticeable when a colourless enamel is applied, but if a tinted one has been used the effect is grotesque. Before applying a second coating of enamel, the remains of the first must be removed. This may be done by painting on the enamel itself and then rubbing off with a cloth, or better still, by using Acetone in the same way.

(Poucher, 1926. p. 71)

By the end of the 1930s, dedicated nail polish removers had been added to most manicure lines, the formulation of liquid nail polish formulations had improved considerably, as had the packaging of these items.

Above: 1936 Manicure sets of polish and remover from Revlon, Cutex (Northam Warren) and Peggy Sage (Northam Warren).

Components

All modern nail polishes have four main components: film formers, solvents, resins and plasticisers. Coloured nail enamels can also contain pigments and pearlescent materials as well as suspension agents to help stop the pigments from settling out. Other ingredients such as U.V. filters and proteins were added later.

Film formers

The film-former is the glossy coat that is left on the surface of the nail after the solvents have evaporated. As previously noted, until nitrocellulose became the film-former of choice, a range of substances were used including gum benzoin, shellac and waxes.

Over the years, other film-forming substances have been proposed as substitutes for nitrocellulose, one of the earliest being cellulose acetate, also used in ‘safety film’. There are nitrocellulose-free nail polishes on the market today but nitrocellulose is still the commonest film-former used. It has a low solvent retention and dries quickly to form a waterproof, tough film.

Nitrocellulose is outstanding for its hardness, toughness, resistance to abrasion, and excellent solvent release. It is interesting to note that nitrocellulose is also the oldest man-made substance among the film-forming agents which dry solely by evaporation and without any subsequent oxidation or polymerization.

(Peirano, 1957, p. 678)

As noted earlier, nitrocellulose comes in a range of grades depending on its level of nitration. This affects its volatility and solubility; highly nitrated nitrocellulose being more volatile and less soluble, lower nitrated forms being less volatile and more soluble.

A second characteristic of nitrocellulose that affects its use in nail polish is the length of the polymer chains that make it up. Shorter chains result in a more brittle film that has a lower viscosity, while longer chains make it softer and more viscous. Polishes that have a low viscosity will not adhere well to the brush and will not give a thick enough coat, while those that are very viscous will not flow easily and leave a coat that is too thick and streaky. Consequently, nitrocelluloses with medium length polymer chains are the types most commonly used in nail polishes, identified as E27 and E32 in Europe or ¼ and ½ RS grades in the United States.

Plasticisers

Nitrocellulose produces a tough, transparent film but is also brittle so the polish will crack and flake if it is used in isolation. To make the polish more flexible, solid and liquid plasticisers are used. Liquid plasticisers, such as castor oil, produce a soft, flexible polish, while solid plasticisers, such as camphor, generate a harder film. To get the best of both worlds both types were used with castor oil and camphor being the commonest plasticisers used in early nail polishes. Castor oil is no longer used and although camphor is still found occasionally in some polishes, both of these early plasticisers have been largely replaced by better substitutes.

Resins

Resins are added to nail polish to help it adhere to the nail plate so that chipping or peeling are reduced. They can also make the polish tougher and improve gloss. Two main forms are used: natural resins – like benzoin, de-waxed dammar, mastic sandarac, shellac and benzoin – and synthetic forms.

Until the 1930s, most of resins used were natural and they suffered from a number of drawbacks. Some, like benzoin, darkened when exposed to light and most required some burnishing of the nail plate after the polish had dried to bring out the full gloss. Being natural products there were also issues with batch uniformity and rising costs.

In 1938, the synthetic resin, tolulene-sulphonamide-formaldehyde (TSFR or TSAfr), was introduced into nail polishes and gained wide use. As well as being colorless and transparent it made the nitrocellulose film tougher and improved its adhesion. Unfortunately, in 1943, TSFR was identified as a common cause of allergic contact dermatitis. Symptoms could appear around the nail but a common site of an allergic reaction was the eyelids, due to users rubbing their fingers against their eyelids when their eyes were sore or ‘tired’.

TSFR is still found in nail polishes today, generally listed ether as tosylamide/formaldehyde resin or toluenesulfonamide/formaldehyde resin, but some manufacturers avoid it. Some go even further and along with camphor and dibutyl phthalate (DBP) – an early plasticiser banned by the European Union in 1976 – specifically list TSFR as being absent.

Solvents

A large number of solvents chave been used in nitrocellulose-based nail polish. Selecting the type and proportion depends on a number of factors including drying time, cost, and odour.

Above: 1939 Bette Davis blowing on a Revlon nail enamel to speed up the drying time.

It might be thought that fast-drying solvents would be ideal but this is not necessarily the case. If the nail polish dries too quickly the film may be streaky and the rapid evapouration can cool the polish below the dew-point causing clouding (blushing), particularly on humid days when the water content of the air is high. Best results were therefore obtained by including a range of solvents, some of which have a slower rate of evapouration.

Colour

As mentioned previously, until the 1930s nail polishes were largely coloured with soluble dyes like carmoisine, safranine, erythrosine and phloxine. These were easy to incorporate into nail polish, the only major problem being that they often stained the nail.

The first nail polishes that included suspended particles appeared in the 1920s. These were the pearl polishes – made with fish essence from fish scales – and metallic polishes – that used bronze, silver or gold metallic powders. The use of other suspended pigments such as titanium dioxide and iron oxides occurred in the late 1920s when opaque cream polishes were developed. In the United States, these became more common a few years before the 1938 Food, Drug and Cosmetic Act (FD&CA) and the introduction by the American Food and Drug Administration (FDA) of an approved list of colours that could be used in cosmetics. By this time, the fashion for matching nail polish and lipstick had taken hold in the United States and similar pigments began to be used in both lines.

The early pearl and metallic polishes experienced a degree of sedimentation – settling out of the solid particles – but the problem became more acute when cream polishes replaced transparent forms. The issue was made more difficult by the fact that the sedimentation rates of the different powders differed. For example, pearlessences made from fish scales settled more slowly that those made from bismuth oxychloride.

Of particular concern was the white pigment, titanium dioxide. Being heavier than iron oxides it settled first. Once settled it was difficult to get it to back into the mixture so a white residue developed on the bottom of the bottle. A number of solutions to the problem were tried over the years including: adding a stirring stick to mix the polish before use; deliberately coarse-grinding the iron oxides so that they would settle with the titanium dioxide to produce a residue that was reddish rather than stark white; covering the titanium dioxide particles with colour so that they were was not as noticeable when settling out; designing bottles to hide any sediment that might appear; and adding instructions to shake the bottle vigorously before use.

The ultimate solution to the problem was to develop a nail polish that was highly thixotropic; i.e., was thick and viscous when still but thin and less viscous when applied. A number of compounds were tried over the years but synthetic bentonite and hectorite clays proved to be the most effective and, although not without their problems, many nail polishes still contain stearalkonium hectorite or stearalkonium bentonite to this day.

Base coats and top coats

One way to achieve good adherence, reduce staining and improve hardness, colour and gloss was to use a base coat before applying the polish and then follow that with a top coat. The three products contained similar ingredients but differed in the amounts used. A base coat has more resin to help it adhere to the nail and reduce chipping, while the top coat contains less resin but more plasticiser and nitrocellulose to improve gloss and resistance to wear. A layer of colour was applied between the base and top coat, although top coats often contained colour as well.

(parts by weight) Base

coatClear

lacquerTop

coatNitrocellulose (dry) RS 1/2 sec 10 15.00 16 Sanolite resin 10 7.50 4 Dibutyl phthalate 2 3.75 5 Butyl acetate - 29.35 10 Ethyl acetate 34 - 10 Ethyl alcohol 5 6.40 10 Butyl alcohol - 1.10 - Tolulene 39 36.90 45 100 100.00 100 (Wing, 1941, p. 1005)

Base coats appeared before the Second World War but were often sold as nail protectors to help stop the nail from splitting or breaking. Examples included Nail-Cote (Glazo), Nail-O-Wax (Juliette Marglen), Nail Protecta (Elizabeth Arden), Stazon (La Cross), Prolon (Revlon), and Nail Creme (Barbara Bates).

Above: 1938 Revlon Prolon.

New formulations, such as Perma-Nail (Perma-Nail, 1946), Everon (Revlon, 1947), Fulpruf Undercoat (Elizabeth Arden, 1947) were developed after the war. A number of these contained phenyl-formaldehyde resins and were associated with reports of allergic contact dermatitis.

Top coats were also produced in the 1930s, one of the first being Juliette Marglen’s Seal-O-Wax (1938). Despite the name it did not contain any wax.

Above: 1938 Julia Marglen Seal-O-Wax.

Base coats and top coats formed a part of many professional manicures well up to the end of the twentieth century but for the average consumer they were too much trouble. In the 1950s, many manufacturers made much of the fact that their polishes did not require either, Charles of the Ritz being one of the first to do so with their Fresh Paint polishes.

Bottles

No discussion of nail polish can be complete without mentioning their bottles. Early nail polishes bottles were very primitive with the mixture generally sealed with a cork or rubber stopper to prevent the solvent from evaporating. A rubbery material that covered the cork or rubber stopped had to be removed before the polish could be used. A brush was included with the polish with, attached to a cork which could be used to seal the polish after the bottle was opened. Corks were very unsatisfactory as they tended to get stuck in the bottles and break but were more commonly used than rubber presumably because they were cheaper.

Above: An early Glazo Liquid Nail Polish and Remover typically found in the 1920s. The bottles are stoppered with corks rather than capped with a screw-top lid, and are sealed with a latex-like material to reduce evapouration while waiting to be sold. The brush was separate from the bottle and was generally of poor quality.

In the early 1930s cork and rubber stoppers were replaced with screw-top plastic lids made from Bakelite or something similar. There were also significant improvements in the quality of the brush which was now fixed into the cap. By 1932, most American companies selling nail polish had switched to these new caps with an in-built brush. As well as making it easier to open, apply and reseal the nail polish, the brush was also less likely to touch the surface than the old corked brushes if it was set down.

Above: 1931 Glazo Manicure Set with Bakelite lids.

Bottles with a Bakelite cap was less likely to spill when being carried. This opened the possibility for developing a wide range of travelling manicure cases which included capped bottles of nail polish and remover.

The addition of titanium dioxide and iron oxide pigments in the 1930s, saw triangular-shaped bottles became more common. This was done for a number of reasons. It ensured that pigments settled on the bottom rather than on the sides of the glass bottles; minimised any signs of floating artifacts or streaks that might appear on the top of the polish; and gave the bottle a low center of gravity that helped stop it from tipping over and spilling as it was used. The tipping problem increased when extra long handles were added to nail polish bottles in the late 1950s. These larger handles were said to make applying the nail polish easier but were a short-lived trend.

The introduction of thixotropic nail polishes made the use of triangular bottles largely redundant, enabling nail polish manufacturers to produced the wide variety of distinctive bottle shapes we see today.

First Posted: 21st April 2014

Last Update: 7th August 2024

Sources

Arend, A. G. (1935). Nail polishes and enamels. Perfumery and Essential Oil Record. April, 122-124.

Bennett, H. (Ed.). (1935). The chemical formulary. A condensed collection of valuable, timely, practical formulae for making thousands of products in all fields of industry (Vol. 2). New York: Chemical Publishing Co., Inc.

British pharmacopœia. (1885). London: Spottiswoode & Co.

Bundock, R. (1933). Modern manicure preparations. The Manufacturing Chemist. November, 323-325.

Butterick Publishing Company. (1892). Beauty its attainment and preservation (2nd ed.). New York: Author.

deNavarre, M. G. (1941). The chemistry and manufacture of cosmetics. Boston: D. Van Nostrand Company.

Durvelle, J.-P. (1923). The preparation of perfumes and cosmetics. (E. J. Parry, Trans.). New York: D. Van Nostrand Company.

E. I. du Pont de Nemours & Company, Inc. (1925). Clear & colored finishes. General information on their many uses, application, colors, color mixing, etc. Parlin, NJ: Author.

Gattefossé, R. M. (1959). Formulary of perfumes and cosmetics. (Trans.). New York: Chemical Publishing Co., Inc.

Hanckel, A. E. (1937). The beauty culture handbook: A modern textbook of beauty culture and hairdressing for beauty parlour assistants and ladies desirous of practising self-treatment. London: Sir Isaac Pitman & Sons, Ltd.

History of the discovery and mode of application of the liquid court plaster, or ethereal solution of prepared cotton, originally applied to surgery by J. F. Maynard. With surgical cases treated, and testimonials from Dr. J. Mason Warren, of Boston, and Dr. Whitney, of Dedham. (1848). Boston: Maynard & Noyes.

Holmes, G. E. (1942). Production of nail lacquer from film scrap. Manufacturing Chemist and Manufacturing Perfumer. XIII(5), 118-119.

Peirano, J. (1957). Nail lacquers and removers. In E. Sagarin (Ed.). Cosmetics: Science and technology (pp. 678-692). New York: Interscience Publishers, Inc.

Poucher, W. A. (1926). Eve’s beauty secrets. London: Chapman & Hall, Ltd.

Poucher, W. A. (1932). Perfumes, cosmetics and soaps (4th ed., Vol 2). London: Chapman & Hall, Ltd.

Sabin, A. H. (1904). The industrial and artistic technology of paint and varnish. New York: John Wiley & Sons.

Silman, H. (1935). Nail polishes. The Manufacturing Chemist. July, 223-227.

Wing, H. J. (1941). Nail preparations. In M. G. deNavarre. The chemistry and manufacture of cosmetics (pp. 983-1010). Boston: D. Van Nostrand Company.

Wing, H. J. (1948). Liquid nail polish. Manufacturing Chemist and Manufacturing Perfumer. XIX(3), 105-108.

Worden, E. C. (1911). Nitrocellulose industry. London: Constable and Company, Ltd.

1903 New-Skin Liquid Court Plaster. Court plasters are believed to be the forerunner of modern nail polishes. They owe their name to the beauty spots made from silk or taffeta that were so admired in the royal courts of Europe during the eighteenth century. Although not all liquid court plasters were made using cellulose nitrate (nitrocellulose) many were.

1903 The Bijou Fluid used in Liquid Court Plaster and Nail Enamel.

1913 Kraska Liquid Nail Polish.

1920 Glazo Nail Polish. Fostering the idea that you no longer had to buff the nail.

1924 Cutex Liquid Polish. The polish is corked and sealed to prevent evaporation and a brush is included, attached to its own cork.

1926 Lesquendieu Eclador (Britain).

1930 Coty Perfumed Manicure Polish and Liquid Polish Solvent. Perfume was often used to help hide the smell of the solvent.

1930 Peggy Sage. The three matching nail polish and lipstick shades were Palm Beach Coral, Biarritz Red and Lido Crimson.

1930 Glazo Polish Packs.

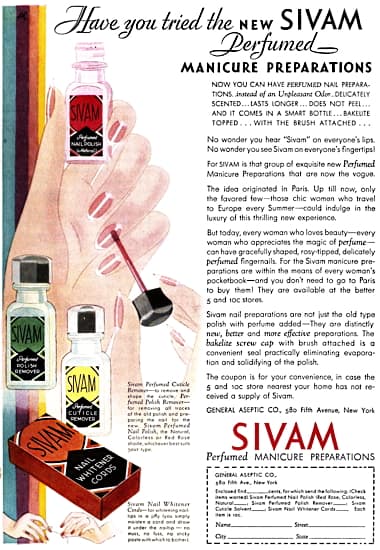

1930 Sivam.

1932 Cutex Nail Polish. As the largest selling American nail polish until the 1940s, Cutex played a key role in getting the average American woman to use nail polish. However, the company was very reticent about introducing vivid colours.

1932 Oja (France).

1933 Vareen Liquid Nail Polish (Britain).

1935 Hercules Powder promoting the use of nitrocellulose lacquers for labels and packaging.

1935 Cutex matching finger and toe tips.

1935 Saint-Ange (France).

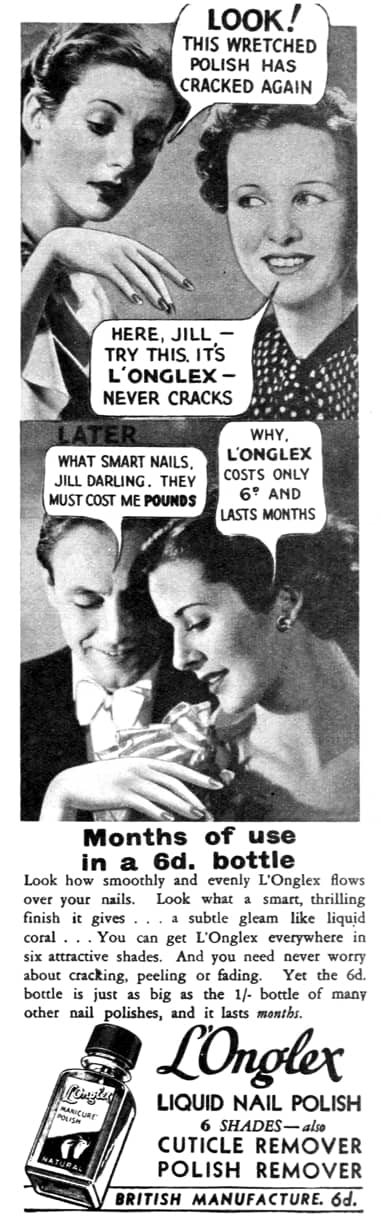

1936 L’onglex Nail Polish, a French brand (Britain).

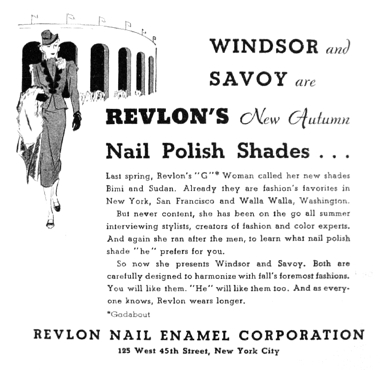

1936 Revlon Nail Enamel Corporation. The company changed its name to Revlon Products after it introduced lipstick into its product line in 1939.

1936 Plat-Num Nail Polish.

1937 Blue Bird.

1937 La Cross.

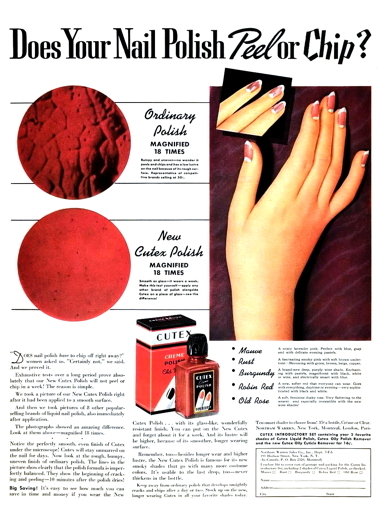

1937 Cutex. Peeling and chipping problems caused by poor adhesion of the polish to the nail plate.

1938 Revlon. Around this time Revlon changed the name of its nail products from polish to enamel as Charles Revlon thought it sounded ‘classier’. Revlon sold their nail polish in a triangular shaped bottle which was very novel for the time.

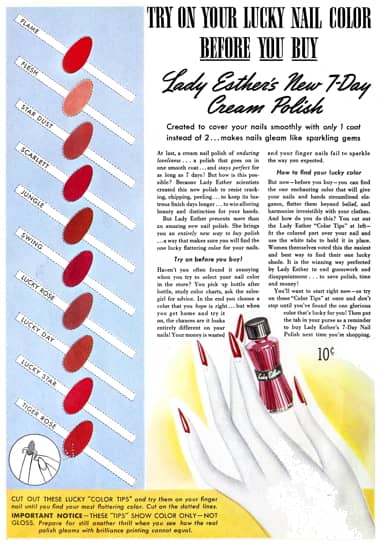

1938 Lady Esther Cream Polish.

1939 Revlon.

1940 Peggy Sage.

1940 Elizabeth Arden.

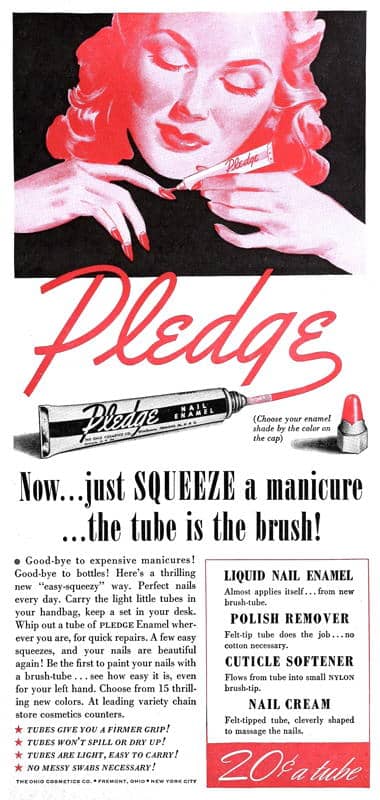

1940 Ohio Cosmetics Pledge Liquid Nail Enamel dispensed in a tube.

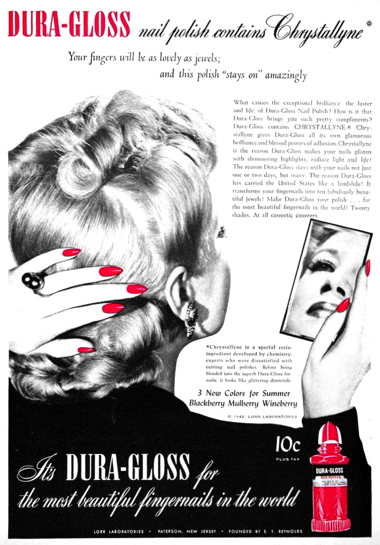

1942 Dura-Gloss bottle lids shaped to resemble a nail.

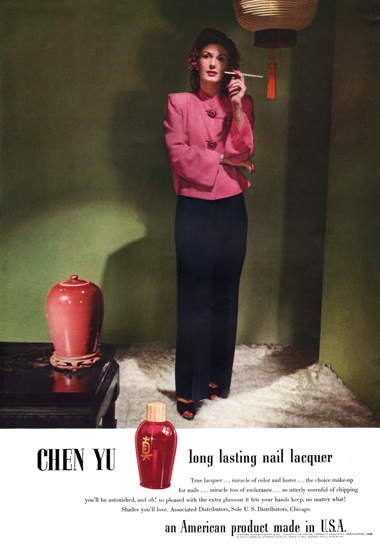

1943 Chen-Yu. The company consistently referred to their nail polishes as a nail lacquers and used exotic oriental themes in their advertising.

1945 La Cross.

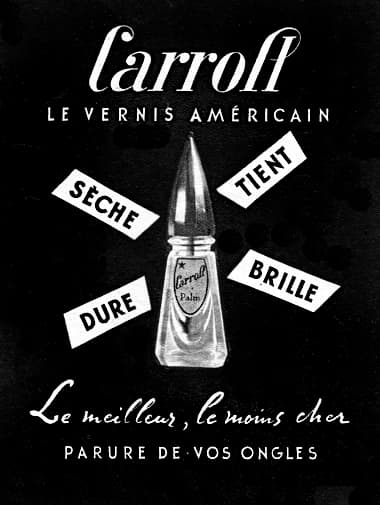

1948 Carroll (France).

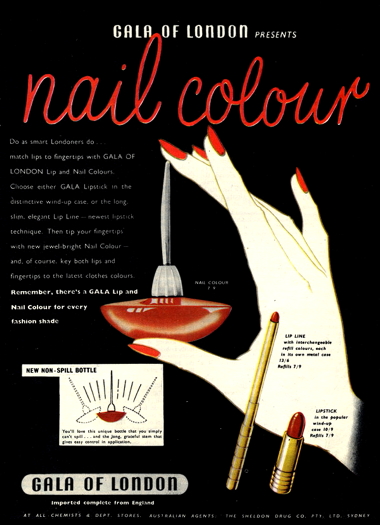

1949 Gala nail polish in a spill-proof bottle.

1950 Dorothy Gray Red Trey Nail Polish and Lipstick.

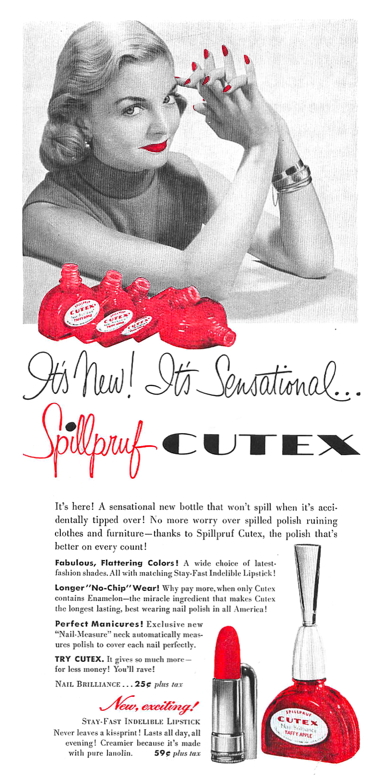

1952 Cutex Spillpruf nail polish produced by modifying the bottle opening and giving the bottle a low centre of gravity.

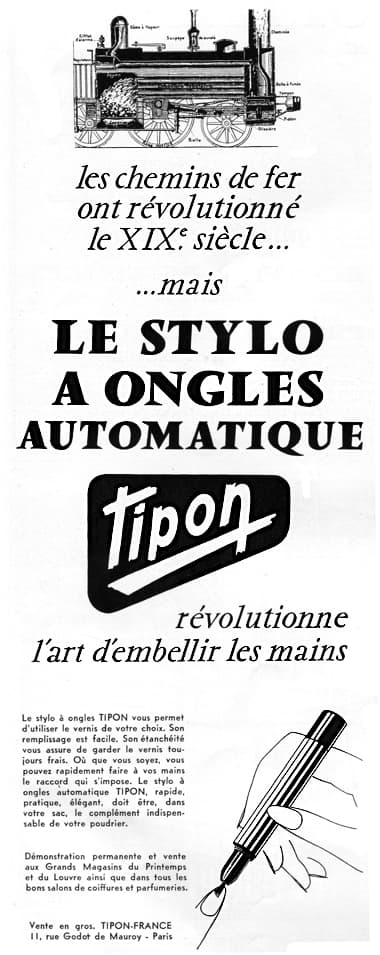

1954 Tipon, a French nail pen used to apply nail polish.

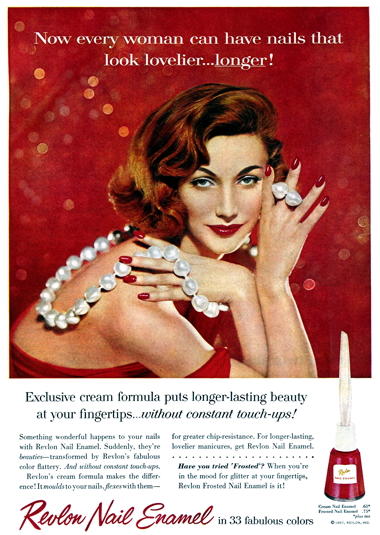

1957 Revlon Nail Enamel in 33 colours in the once common triangular-shaped bottles.

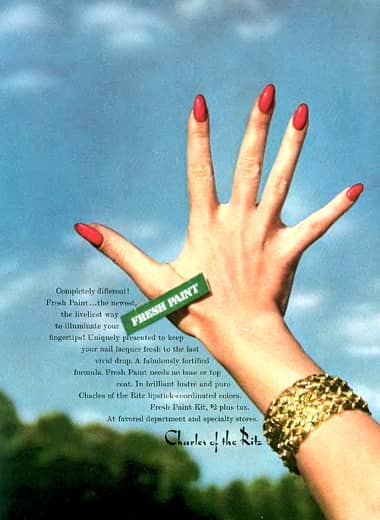

1959 Charles of the Ritz Fresh Paint. “A fabulously fortified formula. Fresh Paint needs no base coat or top coat. In brilliant lustre and pure Charles of the Ritz lipstick-coordinated colors.”

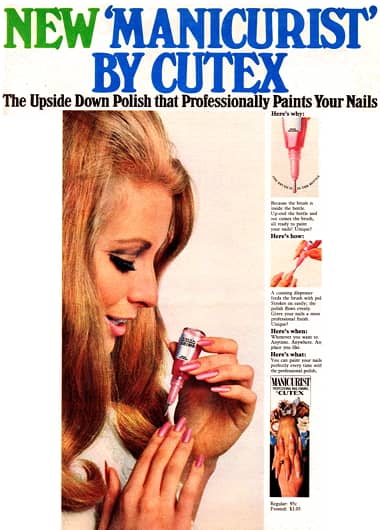

1968 Cutex Manicurist (Australia). A number of different application methods for applying nail polish have been tried over the years, none successfully.